In the field of industrial processes and industrial material separation, efficiency and precision are key elements to ensure the quality of the final product and optimize production. In this context, I-mec has recently introduced a revolutionary innovation in the field of screening: the circular vibrating screen with dynamic vibration control, model MT-X.

In this article, we will explain the meaning and role of this device in the process of selection and distribution of materials in industrial processes.

What is a vibrating screen and how does it work

A vibrating screen is a device used to separate solid materials of different sizes through a mechanical sieving process. The operation is based on a vibratory movement that passes the material through one or more screens with meshes of specific dimensions. Vibrating screens find application in numerous sectors, including the ceramic industry, the food sector, pharmaceutical production, recycling and waste treatment.

For more information on their characteristics and applications, we have written an article that offers a comprehensive overview of types and sectors of use, as well as specific details on the heavy-duty MT series of which the MT-X model is part.

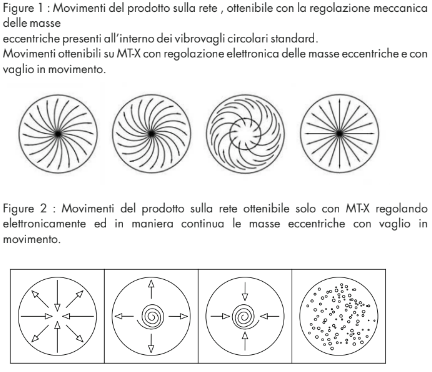

The innovation of dynamic control

The new MT-X vibrating screen, presented by I-mec at the International Exhibition of Technologies and Supplies for Surfaces (Tecna) in Rimini, at the end of September 2024, represents a significant step forward in screening technology. This model is distinguished by a fundamental characteristic: dynamic control of vibration.

The ability to electronically adjust operating parameters while the machine is in operation constitutes a revolutionary innovation in production process optimization, both from a time perspective and in terms of final product quality. Unlike traditional vibrating screens, which require interruption of the current program to modify motor or vibration settings, the MT-X model allows adjustments to be made in real time.

Intuitive digital interface

The heart of this innovation is represented by a digital and intuitive interface, which allows constant monitoring of operating parameters and recalibration, with active machines, of crucial values such as rotation speed, mass phasing, product rotation direction on the screen, and vibrator motor temperature.

Circular vibrating screens: efficiency and versatility

The circular vibrating screens are essential devices for the separation of industrial materials. These machines consist of a vibrating element, an elastic one and a fixed one, which are combined to ensure optimal performance. The flexibility of our devices extends to the possibility of creating dedicated systems and coupling them with other components, forming the so-called “skids“. These pre-assembled plants offer significant advantages in terms of installation efficiency and space optimization. All I-mec vibrating screens, including the innovative MT-X model, comply with CE regulations, with additional certifications available upon request.

Technical characteristics of the MT-X vibrating screen

The advanced technology of the patented MT-X circular vibrating screen improves efficiency and performance compared to traditional models and is also very versatile, lending itself to wide use in different sectors.

All adjustments are electronically controlled, even remotely. Technicians can thus constantly monitor operating parameters and adapt the machine to different conditions during operation, without having to stop production.

The main characteristics of this new model include:

- electronic phase shifting of mass angles with the machine in motion;

- operation in manual or automatic cycle mode;

- electronic variation of rotation speed;

- reversal of product rotation direction on the screen with the machine in motion;

- change of vibrator motor direction before startup;

- remote control;

- management of operating parameters via touch screen;

- machine equipped with: Inverter, PLC, Touch Screen, Encoder.

The device structure is specifically designed to resist the centrifugal force applied and the strong acceleration that occurs in some transient phases. The contact parts are made of AISI 304 stainless steel, which ensures robustness and durability over time, thus also optimizing maintenance and component replacement costs.

Advantages of the vibrating screen with dynamic control

The introduction of dynamic control in the screening process offers numerous advantages:

- possibility of creating a continuous process with electronic variation of operating parameters with the machine in motion;

- control of operating parameters via touch screen, including absorbed current, vibrator motor temperature, rotation speed, mass phase shift angle, rotation direction and timing of reference values;

- remote control of process parameters;

- PLC-configurable machine according to the product to be screened and the process to be performed;

- structure designed to resist centrifugal forces and accelerations;

- possibility of applying all optional accessories available on vibrating screens manufactured by I-mec.

Thanks to these advanced technologies, process control becomes more efficient. By reducing errors with rapid and targeted interventions, it improves the quality of the final product and minimizes downtime.

Options and customization

The MT-X circular vibrating screen offers various customization options, a common characteristic in products and services offered by I-mec, to adapt to specific customer requirements:

- cycle customization (Pre-set routines);

- predictive maintenance tool;

- integration of additional control sensors;

- ultrasonic system;

- special surface finishes, including mirror polishing, electropolishing and satin finishing;

- versions with surface coatings in Teflon, polyurethane, Rilsan, and others;

- variants with outlets of different sizes or with different connections (flanges, clamps, etc.);

- types with insulated bands;

- gasket kits suitable for every requirement;

- constructions in alternative materials (AISI 316, duplex, super-duplex, etc.);

- models with operation under pressure or vacuum.

Industrial applications

The MT-X vibrating screen finds application in various industrial sectors thanks to its versatility. Mineral processing, the ceramic sector, aggregate production, the agro-food department, recycling of synthetic elements and the chemical and pharmaceutical industry are just some of the fields in which this device can be successfully employed.

The ability to adjust vibration electronically and in real time allows optimization of performance based on the specific requirements of the material to be treated, making this new model suitable for a wide variety of plants.

If you wish to discover how the MT-X vibrating screen can improve your company’s production processes, contact us to receive all the technical specifications of the device. Our experts will be happy to provide personalized consultation and answer any questions regarding this innovative technology patented by I-mec.