The separation of materials, which are mostly liquids, solids or powders, is an operation performed in multiple industrial sectors. Vibrating screens are the instruments that, in many cases, are adopted to perform this task. The various models are distinguished by the application for which they are developed and some are designed for screening substances in different forms.

The design of vibrating screens intended for various commercial sectors constitutes one of our core businesses. We create a wide range of machinery, customized in line with the needs of client companies.

Below we explore the objectives for which they are used, the versions we manufacture, the application fields and the advantages of this equipment.

Functions of Vibrating Screens

These systems are equipped with cutting-edge technologies capable of dividing the material, mainly, for two distinct purposes:

- subjecting it to subsequent processing;

- recycling it for the production of other components in order to reduce waste.

Vibrating screens are driven by an undulatory and vibratory motion that separates particles of large-sized from fine ones. The process involves the passage of liquids, powders, granules or solid substances, dry or wet, through a perforated plane for screening.

The incoming material, after being distributed evenly within the appropriate tank, is shaken to allow the fine part to descend into the correct discharge outlet. The part with larger granulometry is expelled through another channel with the purpose of performing other treatments or grinding it again for other needs.

Characteristics of Vibrating Screens

Each vibrating screen is composed of a static part and a vibrating one. The first consists of a painted carbon steel or stainless steel base that can be fixed to the ground, on a trolley with three or more wheels, on support legs. The vibrating component, supported by support springs, consists of the following elements:

- an electrovibratory motor;

- one or more bands with residue discharge;

- a screen-carrying frame;

- gaskets;

- a disc with one or more discharge outlets;

- a clamping ring with clamps to keep all pieces in position.

Another fundamental part of vibrating screens is the anti-clogging system, formed by cylinders, spheres and an ultrasonic mechanism. The screens for screening differ in the material with which they are built and the dimensions. These factors are related to the substances processed and the fraction that is aimed to be obtained.

Application Sectors of Vibrating Screens

The functions of these devices and their versatility allow to improve numerous production processes carried out in various fields. In fact, vibrating screens divide both liquid and powder components of different sizes to remove foreign bodies, break up any lumps, select particles to be subjected to subsequent treatments and those to be discarded.

The implementation of this equipment accelerates and optimizes the quality control of products. Furthermore, the waste of useful resources is limited as some waste substances are treated in other companies to be reused for different purposes.

We illustrate the sectors in which vibrating screens of our production are used:

- food;

- pharmaceutical;

- ceramic;

- recycling.

Their application fields also extend to construction and other industrial sectors. Contact us to find out if our extensive series of vibrating screens is able to meet the needs of the sector in which you operate.

Our Main Types of Vibrating Screens

We have been designing and selling vibrating screens since the late 1980s with the objective of providing tailor-made solutions that optimize the production processes of client companies active in numerous sectors. Over time we have introduced different equipment and methods, suitable for the evolution of the machinery to be produced.

The updating of our tools always goes hand in hand with the deepening of our skills to offer high-performance, resistant and durable products. The meticulousness with which we operate is, instead, one of the aspects that has remained unchanged and is evident from the accurate controls we perform on each device.

The flexibility of our offer and the extensive warehouse availability, to respond promptly to everyone’s needs, represent other distinctive features of our company. We also have a line of special vibrating screens, precisely to satisfy the needs of our customers.

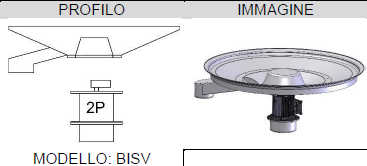

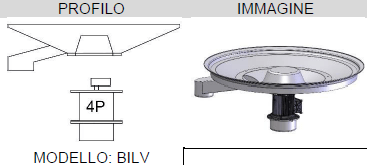

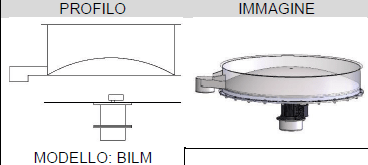

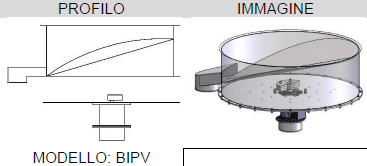

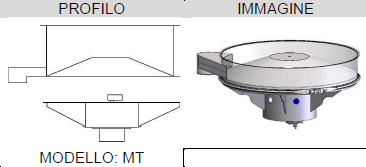

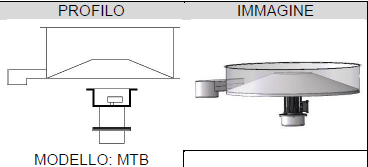

On our website, you will find the types of vibrating screens we develop divided by category. Below we list some with their full name. These designations are only possible if one takes for granted operating in the ceramic sector. If, instead, we decide to talk about the same machinery, but from the point of view of the other sectors previously listed, then we must use the following abbreviations: BISV for glaze vibrating screens, BILV for liquid vibrating screens, BIPV for powder vibrating screens, MT for heavy-duty series vibrating screens, RP for back-press vibrating screens, VR for rectangular vibrating screens, VO for oval vibrating screens and KTS for nutating vibrating screens.

Vibrating Screen for Glazes

Vibrating Screens for Slips and Liquids

Vibrating Screen for Powders

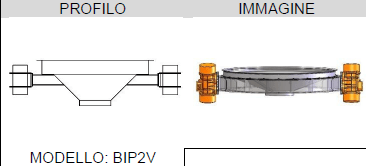

Dual Motor Vibrating Screen for Powders

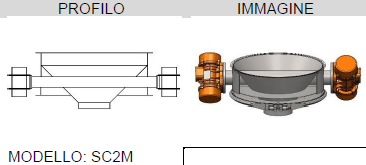

Central Discharge Dual Motor Vibrating Screen for Powders

Heavy duty vibrating screens

Circular Vibrating Screens

We are a worldwide reference point for the design and manufacture of circular vibrating screens equipped with different characteristics depending on the field of use. Each machine consists of three parts fundamental:

- vibrating element which includes band/s, screen pack, screen bottom and motor vibrator/s;

- elastic element formed by springs with buffers or anti-vibration mounts;

- fixed element which can be a base, a spring-carrying flange or a trolley.

Strong from the experience gained, understanding of customers’ particular needs and research for product improvement, we develop a wide range of models of circular vibrating screen. The operating principle is similar, but each element is conceived tailor-made to satisfy specific sectoral requirements or process requirements.

For the treatment of some types of articles we develop systems dedicated to the appropriate process to be carried out. In addition, circular vibrating screens can be coupled with other components, such as pumps, filling stations, bag-breaking stations, deferrizers, electrical panels, big-bag emptiers, etc.

The combination of these devices gives life to the so-called skids, small pre-assembled and tested plants directly in our company before delivery to the customer. Thus, installation times are reduced, additional engineering costs are eliminated, the responsibility for the plant is borne by a single manufacturer, and space requirements are reduced.

All our vibrating screens are built in compliance with the current CE community directive. Other certifications are available only on request for some models.

Advantages of Using Vibrating Screens

Safety, quality and recovery constitute the most important aspects for which the introduction of vibrating screens in your company’s production cycle is profitable. In fact, these instruments eliminate unwanted substances and separate those of different sizes. They therefore play a key role in all areas where products must have specific characteristics to meet established standards.

Finally, vibrating screens promote the circular economy as they serve to divide components destined for different processing significantly reducing waste. In fact, some would be discarded, but can be used for the production of other goods in other sectors. It is a sustainable approach for the planet and advantageous for businesses from an economic point of view.

Do you want specific information about the vibrating screen models we develop? Call us or fill out the form in the contacts section.